|

Incomming Quality Control - IQC

All incoming raw material are checked before used. Varies measurements are taken to check against approved data. Once rejected, raw material are sent back for further examination. |

|

In Process Quality Control - IPQC

We perform inspections during the maufacturing process. Frequency of inspection depends on the quality standard set forth by the project. All manufacture datas are recorded for future reference. |

|

Final Quality Control - FQC

All finished goods are inspected acording to our quality standard for each project. Products are sampled according to the AQL sampling rate before it leave leave our production plant into the warehouse. |

|

Outgoing Quality Control - OQC

Our QC team will ramdomly check any finished goods in the warehouse before it goes out for shipment. This last inspection ensure zero defact goods are shipped to our customer. |

|

Proper Quarantine Procedure

Rejected material are specially marked and move to a quarantine area pending final disposal. Once a product is deem rejected by the QC team, the material is hold until further inspection. Our QC team have right to stop a shipment if product doesn’t meet standard. |

|

Complete Complaint Procedure

All complaints are traceable through our QC system for up to 1 year. Each complaint is follow up with further corrective action by manufacture. Complaints trends are further analysis monthly for further action. |

|

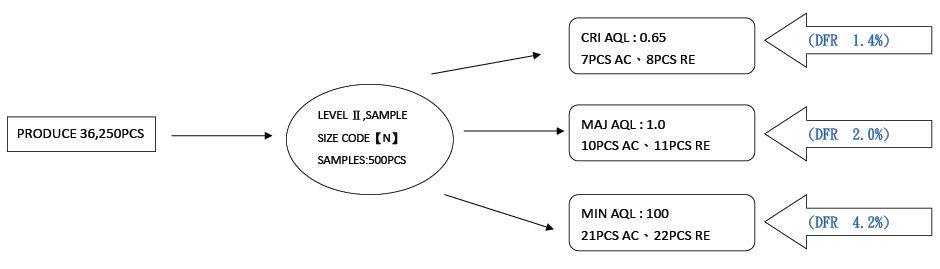

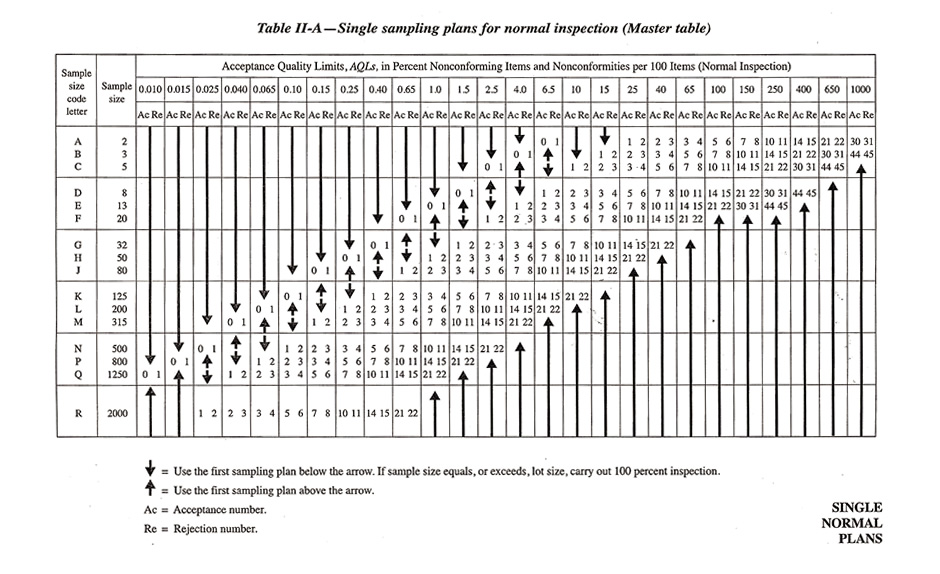

Acceptable Quality Level

We use a strict Acceptable Quality Level measurment for all our product. AQL is a statistical measurement of the maximum number of defective goods considered acceptable in a particular sample size. If the AQL is not reached for a particular smapling of goods, we will review various parameters in the production process to determine the areas causing the defects. Please see below our AQL standard. |